Selecting NEMA motors: TEFC vs. Severe Duty vs. IEEE 841

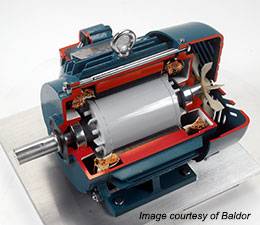

Selecting NEMA motors- TEFC, severe duty, or IEEE 841

Making the right choice for low voltage motors can greatly affect total cost and reliability. There are so many types and manufacturers of motors that it can be difficult to make the right selection for any given application. Our test teams and repair shops will occasionally find motors that are not matched to the application, often causing premature failure. A few examples to avoid are:

- Continued reliance on open, drip proof (ODP) motors.

- Using general purpose AC motors in heavy process environments

- Applying severe duty motors to applications that require a full, IEEE 841 motor type.

A few items to consider when selecting NEMA motors are:

- If the motor is a replacement, why did the last one fail?

- Where is the motor going to be located (environment/temp)?

- What airborne contaminants (including water) will it be exposed to?

- How is the motor powered (starter, Variable Frequency Drives (VFD), Soft Start, etc…)?

- What is the load, how is it coupled, and what is the speed range?

Some suggestions for selecting NEMA motors include:

If you want to ensure the motor decision you’re making will yield the longest run life consider the following:

- A totally enclosed fan cooled (TEFC) should be the standard starting point. Replace ODP motors, and upgrade to TEFC. This is one topic worthy of additional coverage and we will have another post on it.

- All motors placed outdoors should be severe duty rated or higher.

- Motors exposed to airborne contaminants (ash, paper, etc), frequent temperature variation, and the greater stress of the process industry should be replaced with severe duty as a minimum.

- When severe duty does not hold up, as often in the case of the paper, metals, and chemical industries, it usually makes sense to upgrade to IEEE 841. These motors are built to last in a process environment.

Lastly, make sure you know what your vendors are quoting, and request more than just a part number. Require that a data sheet be provided to ensure you are getting a motor that will offer you the best choice. Our customer service teams are trained to ensure the right motor is being quoted for the application and we would be glad to help.

View other articles below: