Strategic Approach to Pandemic Demand

When the COVID-19 virus impacted the world in 2020 a chemical manufacturer South Carolina was faced with growth demands they never imagined.

All businesses are trying to grow and increase their market presence year over year. Some years are better than others, but the goal is always to grow. When the COVID-19 virus impacted the world in 2020 a chemical manufacturer South Carolina was faced with growth demands they never imagined. This time their demand was for acrylic base polymers which are a key ingredient for making hand sanitizer. They saw this as an opportunity to protect many people and ultimately save lives from this new and scary virus. The story of how they approached the demand surge is insightful and provided many lessons that others can learn from.

Problem: Scale overnight to meet demand

The plant in South Carolina produces other products and support many industries with their solutions. Overnight the need for the acrylic based polymers dramatically increased and they were faced with solving the challenge of how to rapidly expand with additional production lines. While they were beginning to put together a plan of action, demand for these products continued to surge and required that still more production lines be added. This can be overwhelming for any plant to manage and handling it in the middle of a pandemic raises the level of angst tremendously.

Solution: Work smarter and harder

They made the strategic decision to step back before moving forward and truly understand what enhancements they needed prior to any work being completed. This proved to be the winning strategy that allowed them to engineer a robust system that is designed with future scalability and flexibility for further expansions. So how did it all start? As with most things in business it starts with one conversation at a time. The team at EECO was visiting the site and they shared the news of the expansion and some of the items they would need to begin. From this discussion the conversation began to expand around new and evolving technology that they were unfamiliar with.

Explore all the technology available.

Many industrial facilities have their sweet spot of comfort in terms of automation and power providers. Typically, once incumbents are established the path of least resistance is to keep alignment with those providers. This is where they changed the game. They decided to take this opportunity for expansion as one to learn about other solutions available to give them the best system possible (not the easiest).

They had intense deadlines to meet and began the process of evaluation by having the Engineering and Services team at EECO provide onsite demonstrations of some of these new technologies. Items such as variable frequency drive and automation solutions were showcased which allowed their team to test the functionality and learn new possibilities in a fast and efficient manner. With the time restrictions in front of them a visit to EECO’s Connected Power Lab in Columbia was not possible so the team brought the lab to them – virtually!

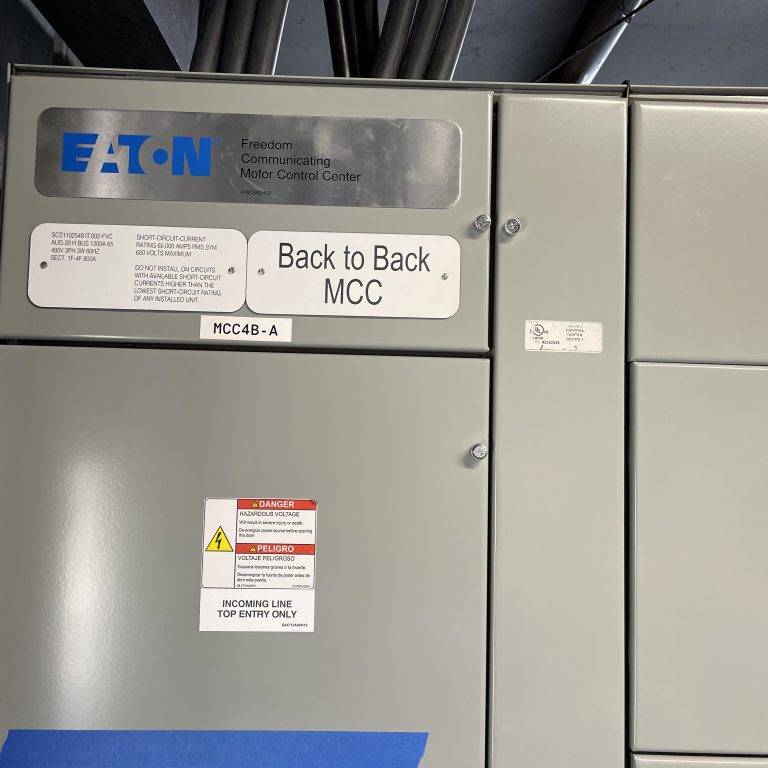

Through a safe and reliable virtual private network connection they were able to experience several solutions available at the Columbia lab from the comfort of their site. It was during this experience that they were able to see firsthand how new intelligent motor control centers can interact with automation systems. They also spent extensive time learning about available data from smart motor protection and how to utilize that data in their process to make better, faster, and in the moment decisions. One of the largest pieces of the puzzle they were able to experience thru this was the connectivity options. From their site they were able to diagnose, troubleshoot and correct items in the Columbia lab. This was the icing on the cake and they now had a new expectation for their desired solution.

Send the project out for bid

After they took time to conduct such extensive homework the bidding process began. The incumbent provider and others were invited to participate in this process. As options were evaluated they determined that since EECO took the time to understand their needs, introduced new technologies and provided technical support they would be awarded the project. The proposals with outdated technology were not considered as they saw value in how new connectivity and available data would impact their site.

During project commissioning they recognized several other benefits from such an integrated solution. The control wiring inside the intelligent motor control center was greatly reduced. When the main source of control is over Ethernet/IP one cable can take the place of many. In their case it is estimated that over 200 individual wire runs, and terminations were eliminated with the intelligent MCC. The contractor that installed the equipment finished ahead of schedule and after initial configuration the solution was providing data, they never knew was available.

Reap the reward

They managed a surge in market demand with grace and wisdom. They knew that jumping ahead with the mindset that “we’ve always done it that way” would not lead them to where they wanted to be in the future. It was by taking the time to evaluate technology, gaining trust in outside partners and focusing on modernization for future capability that fueled their incredible decisions. They are a true testament of how to handle adverse challenges and have a successful outcome. Their increased production allowed their company to grow but more importantly helped keep many people in the world safe and healthy throughout a worldwide pandemic.

Have an upcoming project and need guidance?

Schedule an appointment today and learn more about Intelligent MCCs