New VFDs Require High Speed Fusing Protection

Don't Get Caught Without High Speed Fusing

Over the years major manufacturers have removed internal semiconductor fuses to cut costs. Most are recommending standard circuit breakers or fuses recommended by NEC for protection, again to minimize installed costs. While this will protect the circuit and the motor, the internal components of the VFD are unprotected.

Most VFD failures occur from overvoltage and transient voltage conditions. Left unprotected, this will result in a shorted IGBT.

IGBT failures usually lead to rupture and melting of bonding wires, also damaging other components, such as capacitors. Only a high speed fuse can prevent this.

Benefits of High Speed VFD Fusing:

- During a short circuit fault, only a high speed fuse will limit the amount of energy rushing into the drive and isolate the damage at the component level.

- Using a high speed fuse protects components and equipment from a violent rupture if a short circuit occurs. This will ensure that the drive can simply be replaced, facilitating maintenance and reducing down time. The failed drive can usually be repaired.

- A high speed fuse lowers the possibility of personal injury from conditions such as arc flash.

Additional Resources

- Are high speed VFD fuses worth it?

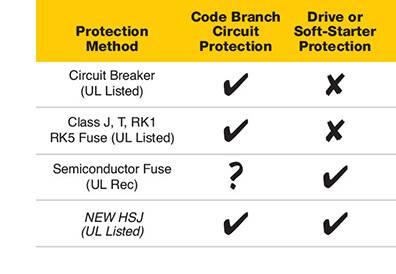

- Is branch circuit protection enough

- Short circuit protection and safety evaluation

- Mitigating arc flash hazards with current limiting fuses