Smart Manufacturing is Changing Industrial Automation

Access to data is revolutionizing the industry and connectivity is the key.

Connected factories use sensors to provide access to unprecedented amounts of real-time data — trusted data that will transform the way you make decisions plant-wide. Adopting a modernization strategy, even just small, progressive upgrades applied according to plant needs, is crucial in an effort to evolve with the future of manufacturing.

Modernization for Aging Automation Equipment

No need to rip and replace. We’ll help you update at your pace, in your time.

Learn MoreEtherNet/IP, Connectivity, and Smart Manufacturing Services

Access to your data will change the way you do business. We can get you started at a manageable pace.

Learn MoreGetting Started with Smart Manufacturing

We created a guide to help you educate yourself and to break up this journey into small, progressive steps.

Learn MoreWhat We Do

The actual path to “smart” does not have to be an expensive, complicated endeavor. This three-step approach follows the concept of progression: taking small steps today toward a fully enabled tomorrow.

The Installed Base Evaluation (IBE)

The blueprint for modernization. Get a handle on what you have in place – from opportunities to threats. Read this to learn more about IBEs.

Learn More

The Smart Tech Review

Get a first-hand demo of the available technology based on the discovery from your IBE. Read this to learn more about Smart Tech Reviews.

Learn More

Planning Your Progression

Device Standards - Information and device-level planning templates to help you think through your requirements and set device standards.

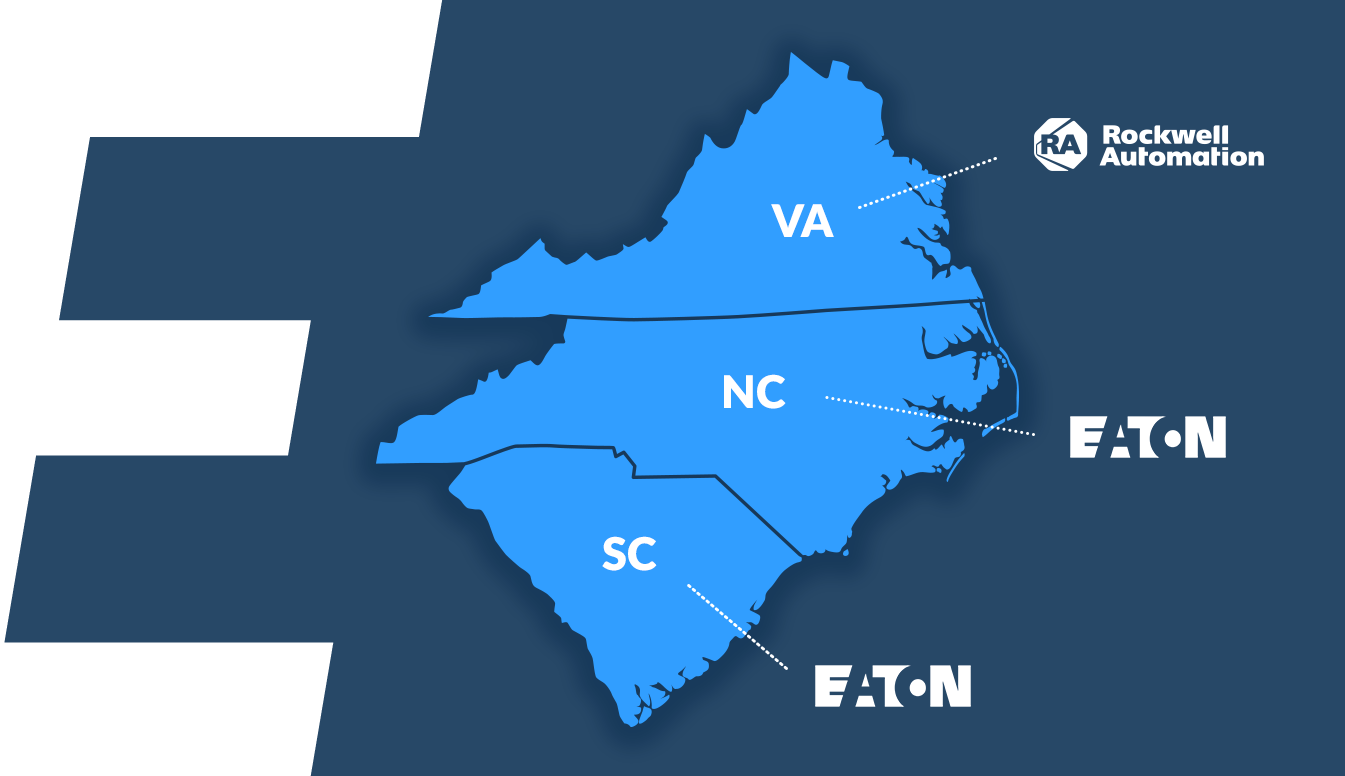

Learn MoreWhere We Do It

EECO is a regional distributor for Virginia, North Carolina, and South Carolina.

Electrical Equipment Company is redefining the expectation of industrial electrical distributors by prioritizing people and Ideas before products. Our commitment to supplying the highest quality of products to our customers whenever and wherever they need is only the beginning.

Modernization for Aging Automation Equipment

Planning for Aging Automation and Control Systems

No need to rip and replace. We’ll help you update at your pace, in your time.

Schedule an IBEMuch of America’s electrical infrastructure is somewhere between end of life and total obsolescence.

How many of your systems are nearing end of life?

75%

Of U.S. plants are more than 20 years old*

$65

BILLION

Of legacy automation systems are reaching end of life*

58%

Of manufacturers do not have an upgrade plan*

How much are aging systems costing industry?

The costs of legacy control and power systems is sobering…

$20

BILLION

In annual unscheduled downtime to industry

Modern systems cost a fraction to support, and offer increased reliability, connectivity and capability.

$100

BILLION

In annual power failures and quality costs

*Arc Advisory Group

How do you start climbing the mountain that is Smart Manufacturing?

IIoT, Industrie 4.0, and Connected Enterprise are a few perspectives on smart manufacturing. There are proven benefits, but the challenge is how to get started. We created a guide to help you educate yourself and to break up this journey into small, progressive steps.

Download the Guide

“Smart Manufacturing (SM) systems are “fully-integrated, collaborative manufacturing systems that respond in real time to meet changing demands and conditions in the factory, in the supply network, and in customer needs.”

– National Institute of Standards and Technology (NIST)

Smart Manufacturing is Proven

At plant (e.g., factory) level, the Smart Manufacturing Leadership Coalition (SMLC) estimates that the demand-driven, efficient use of resources and supplies in highly optimized plants leveraging smart manufacturing techniques will lead to*:

- 10% improvement in overall operating efficiency

- 25% improvement in energy efficiency

- 25% reduction in consumer packaging

- 25% reduction in safety accidents

- 40% reduction in cycle times

- 40% reduction in water usage

*A Policymaker’s Guide to Smart Manufacturing – Stephen Ezell, Economic Benefit – SMLC

Get Started

These tools will help you get started on your journey.

Download The Journey to Smart Manufacturing Guide

Download the GuideDownload sample exercises to help with creative thinking and device specification

(From Chapter 4 “Journey to Smart Manufacturing”)

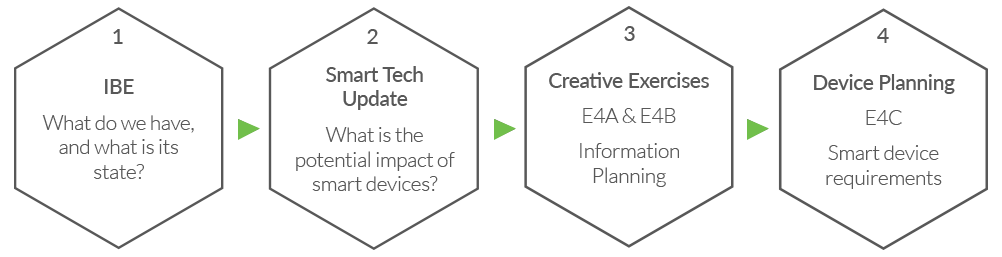

Download the ExercisesThe sample exercises, combined with the IBE and Smart Tech Update, are used to develop clear data and information requirements that steer selection of actual devices. The progression planning process looks like this:

We advocate a deliberate process of progression, working over time toward greater capability. The key is time, and the sooner you get started the better.

Additional Reading

Modernizing your equipment for Smart Manufacturing requires establishment of new practices, awareness of performance benchmarks, and cultural change. These references are a great start to help expand your scope.

Modernization of Industrial Machines

View Resource

MESA International. White Paper 52. Smart Manufacturing – Landscape Explained

View Resource

Enterprise IoT (Internet of Things): Strategies & Best Practices for Connected Products and Services

View Resource

Industrial Ethernet, Second Edition

View Resource

Smart Manufacturing The Next Revolution in Manufacturing by CMTC & SMLC

View Resource