We have all heard the advantages of upgrading industrial lighting to LEDs - lower energy consumption, much longer lamp life, reduced heat build up and better light 'color' among other benefits. If you've ever been in an older facility alight with sodium vapor lamps or other traditional lighting, you know what we're talking about here. Odd looking, washed out colors and overall poor light quality makes it difficult to discern the color of important objects in the industrial environment. But, there's more to the decision to upgrade than the usual considerations.

We conducted an informal poll of our industrial sales personnel who visit these facilities daily and the results were interesting. The number one reason was better ROI on the lighting investment. For most customers this is the financial rationale.

Reasons to Upgrade to LEDs

Longer replacement cycles - This advantage is key component of the financial calculation. Viewed from maintenance a maintenance perspective, there are additional benefits. High bay facilities were mentioned as a great candidate to switch to longer life cycle lighting. The expense of changing lamps where lift equipment is required, weighs heavily in favor of longer life LEDs.

Less hassle to change lamps - Related to the above, this is about the time it takes to effect lamp replacements. Reduced staffing, aging facilities requiring extra maintenance and cost reduction pressures, mean that staffs and resources are stretched thin. Maintenance time is better spent assuring machine or equipment performance than changing lamps.

A better in-use experience overall - This advantage relates to the time required to re-strike in the event of a power disruption and the wait time to start lamps initially where they are not used 24/7. Plus, the uncertainty - is this lamp going to start this time? Instant-on features of LEDs makes them very attractive in this regard.

Other considerations

We have covered some of the advantages of upgrading to LEDs, now let's discuss other considerations that come into play when considering an upgrade. Here the calculation is labor hours plus out of pocket cost if rewiring of lighting circuits is called for.

Lighting fixtures were often placed wherever there was a convenient attachment point, or where a junction box was close by. Our small sales sample verified that rewiring is a consideration especially if the original lighting layout needs to be modified to support new lighting locations.

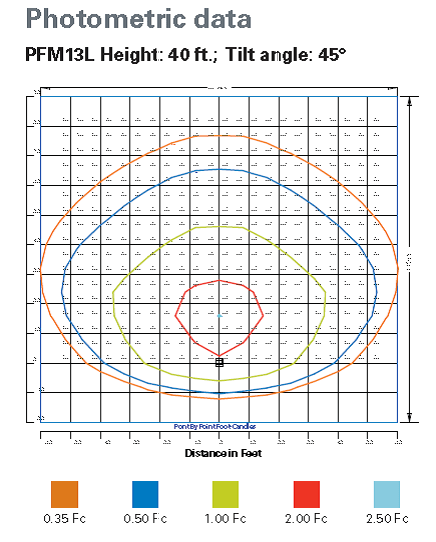

With the advent of CAD applications designed to optimize lighting design, photometric data can give a clear picture of the lighting distribution pattern for selected fixtures, plus other data such as footcandles of lighting power, lighting available at a given axis to the fixture. Photometric data is typically provided as IES or Revit files, which are basically the measurement of distribution of light intensity stored in ASCII format and capable of being modeled in a lighting design (CAD) application. Many lighting fixture suppliers supply these files or image outputs, enabling an advance look at the impact of a re-lighting project.

If rewiring is in scope, due to improper lighting placement, or other factors, photometric data can provide a clear understanding of lighting performance.

Some lighting manufacturers will also design the lighting solution for optimal lighting distribution.

Many customers we work with see LED upgrades as a more or less 'plug and play' solution, replacing outdated, energy inefficient fixtures with new LEDs in the same location. The decision to move fixture locations will depend on the application and its unique requirements.

Free up lighting circuits

In new construction or major upgrades, more energy efficient LEDs can be included on a circuit, thus requiring fewer lighting circuits for the same number of fixtures. Naturally, load calculations would need to be performed but at 3-4 times the efficiency of traditional lighting, fewer lighting circuits free up valuable panel space in load centers or distribution panels. For example, a typical 400W HID can be replaced with a 150W LED fixture providing the same amount of lighting output for roughly a third of the total current.

Careful and complete analysis of the upgrade will yield useful information that affects more than the bottom line. Consult with a local electrical contractor who has done this type work, contact EECO for assistance in selecting the right fixtures.